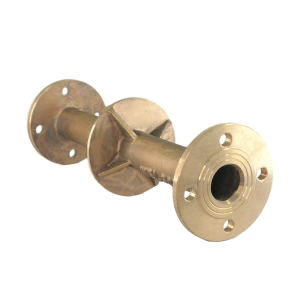

The 106S float operated valve is a mechanical piston-type float valve with excellent corrosion resistant characteristics.

It is designed to function as a controller to flowing liquids supply generally in closed mixing tanks of building.

These available model sizes are from 1″ to 4″ which are mated to the system by flange inlet.

It’s also available in a comprehensive selection of components to match the needs of different applications.

The 106S float valve requires very little operating areas compare to other models thanks to the robust right-angle valve operating design.

The valve also incorporates a pressure balance equilibrium mechanism allowing the valve to shut off more effectively and smoothly.

Service Medium: Water (Fresh / Seawater)

Working Pressure: 0-20 BAR (Non-Shock at normal atmospheric temperature)

The available sizes for model 106S float valve are from 1″ to 4″.

All valve is manufactured with PN16 flange inlet. Valves also include a female screwed joint outlet

The valve main body, piston, and lever are manufactured from high-quality Gr. 316 stainless steel material.

Assembled together by specially designed stainless steel parts to enable this valve to have high corrosion-resistant, and provides reliable operation.

Valve Stainless Steel Material:BS EN 10088-1:2014 Grade 1.4401 (316)

Valve Stainless Steel Component and Parts: As specified to BS EN10088-1: 2014 Grade 1.4301(304) / 1.4401 (316)

Ball Float: Spherical Shape. Available material in copper, 316 stainless steel, or HD-PE plastic

Float Lever: Mount to float by penetrating through its inner cross-section and screwed joint to valve. Available material in 304 and 316 stainless steel.

This valve has been approved by the Hong Kong Water Service Department under its General Acceptance Scheme.

Please contact us for further details.